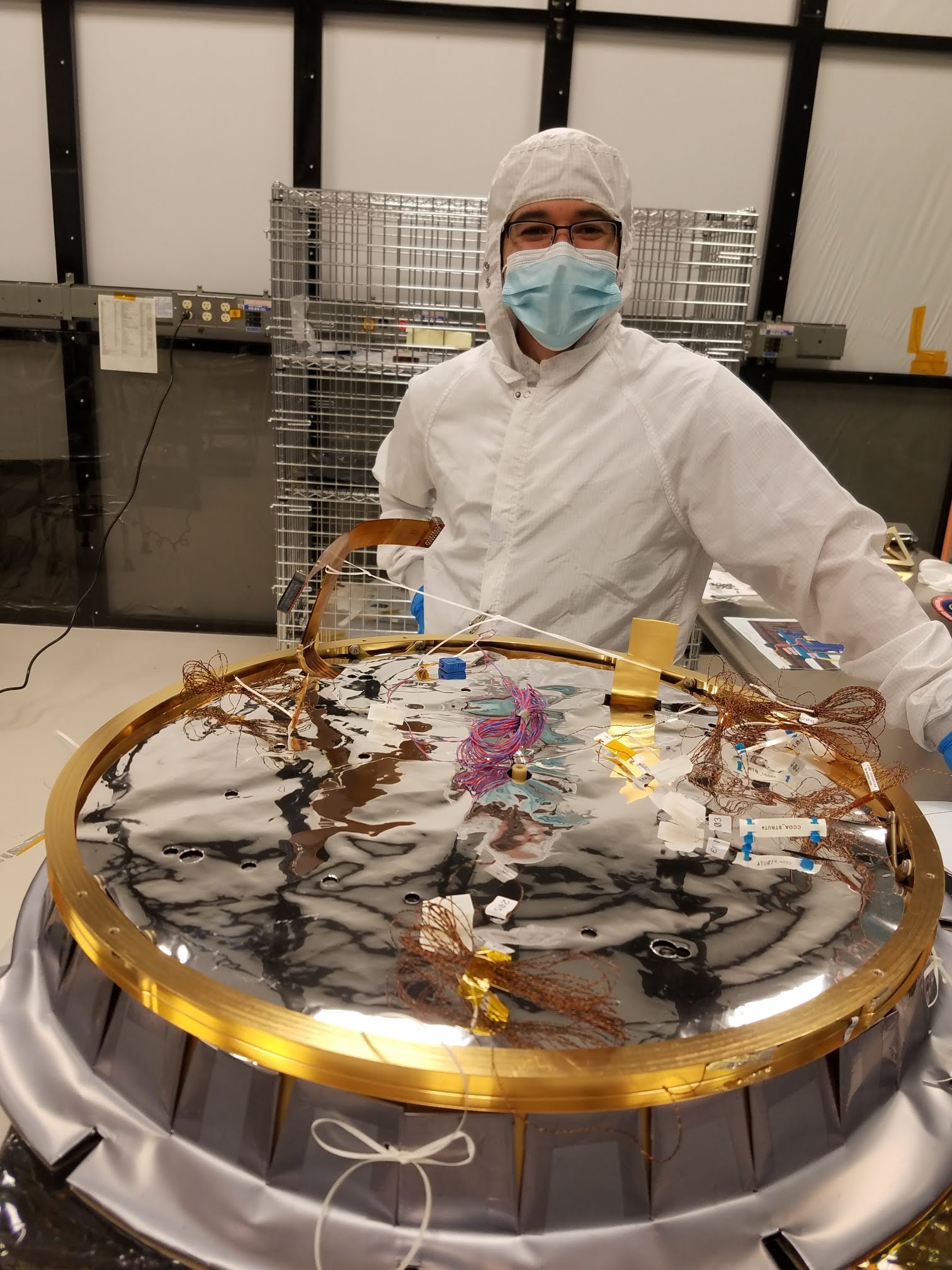

L'Team - Featuring Juan Rodriguez-Ruiz

Nov 10, 2020

While a robot may be the one visiting the Trojan asteroids, people are responsible for getting it there. In L’Team we meet some of the people that make the Lucy Mission possible.

What is your role on the Lucy team?

I’m the thermal subsystem lead for the L’Ralph instrument, which means I have to work with all parts of the L’Ralph hardware to make sure we don’t get too hot or too cold that something stops working out in space. Although for our LEISA detector, too warm would be -250F, so we need to be below that temperature for it to operate properly, which is a big challenge!

Please describe the path you’ve taken to get here.

I’ve been working at the NASA GSFC thermal engineering branch since before I graduated with a bachelor’s degree as a Student Co-op. Since that time I’ve worked on the Lunar Reconnaissance Orbiter, the Global Precipitation Mission, the Dellingr CubeSat, and the IceCube CubeSat, all of which have successfully launched. I was supporting the Roman Space Telescope as the lead SC thermal analyst before coming in as thermal lead for L’Ralph. It has been a fun ride.

Best Lucy team memory?

This has been by far the highest stake project I’ve worked on as a lead. Because of those high stakes, and the high stress environment, there have been several interpersonal disagreements over time. The reason why I rank this as a best Lucy team memory is because in all of those cases, reconciliation has been the outcome, and the recognition that we are in this together and we share a common purpose has prevailed over the disagreement. They have been opportunities to help us grow closer together as a team, and that is awesome!

What Lucy challenges have you overcome? How have you done this?

Getting the LEISA detector to operate below -250F while being passively cooled is a challenge. We had to work with a great level of detail and innovation to get a design that gets us there. We had to work the design to the level of wire traces and the quality of the gold polish in order to meet this challenge. We also used some advanced Multi-Layer-Insulation technology that has never flown on a NASA mission of this class. And we worked with structural designers to get some quality thermal isolators that are thin enough for thermal performance but strong enough for vibration loads. I think we have such a great team, that we were able to take the necessary risks and make the right decisions to get there.

Another challenge I am very proud of successfully tackling is that of addressing the problem of slow moving temperature transitions during thermal vacuum testing (TVAC) because of this type of thermal control architecture. Our simulations showed several days to do some of our transitions. Given our tight planetary launch schedule, I didn’t want to make our TVAC duration run long, or increase the likelihood of cutting out testing in order to meet schedule. To address this problem we designed a heat switch assembly that effectively allows us to cool and warm up much more rapidly than we would’ve using a conventional TVAC test configuration, saving time and money to the project. We just had our first TVAC test with the flight hardware in September, and the heat switch worked phenomenally.

Favorite dessert?

I love carrot cake. So much so that for my wedding last year, in addition to the traditional multi-layer cake, I secretly asked to get a small carrot cake to enjoy. However, the secret got out and people discovered it and it started disappearing quickly. Luckily one of my groomsmen noticed and rushed in for the rescue before it was too late, so I did get my slice.

Favorite COVID pastime?

During the height of the lockdowns me and my wife started Zoom lunches/dinners with friends and family from all over the country, which was a nice way to stay connected.

How would you finish this sentence… The best part of the job is?

Having the opportunity to work with a team that is open to new and creative ideas to solve problems, even if that means stepping outside of our comfort zone in trying those things. And now that we are testing, for me to be able to experience first-hand how all of these design choices are working so well is very rewarding.